What Is Silica Sand?

Silica sand, also known as quartz sand, white sand, or industrial sand, is made up of two main elements: silica and oxygen. Specifically, silica sand is made up of silicon dioxide (SiO2).

The most common form of SiO2 is quartz – a chemically inert and relatively hard mineral. SiO2 grades at a 7 out of 10 on Mohs hardness scale, making it ideal for use as filtration media and abrasive blasting sands.

Although quartz is often white or colourless, it can come in a wide range of shades. The colour of each sand deposit depends largely on the variety of minerals and rock detritus that make up the resource.

In order to be considered a silica sand the material must contain at least 95% SiO2 and less than 0.6% iron oxide. If the sand does not meet this criteria, it will qualify as what’s often called ‘regular’ sand.

How Silica Sand Is Different From Regular Sand

Regular sand, also known as feldspathic sand, brown sand, or construction sand, will always contain some silica, but only in amounts less than 95%. For example, typical brown sand used for concrete applications can contain up to 80% SiO2, along with varying amounts of iron, carbonate, potassium, and other trace elements/minerals.

These ‘impurities’ make regular sand more chemically reactive and often darker in colour when compared to silica sand. The color for non-silica sands (regular sands) can be various shades white, pink, green, and black as well – depending on the geological makeup and geographic location of the sand deposit.

What Is Silica Sand Used For?

There are a number of different uses for silica sand in the industrial and commercial sectors, from golf courses to glassmaking. Silica sand is a commercial and consumer product that is widely available throughout North America.

How silica sand is used depends on physical, chemical, and mechanical characteristics such as grain size, shape, colour, structure, and distribution, as well as refractoriness, strength and stability. These characteristics can differ depending on how the mineral is processed after it is mined.

Here are seven common uses for silica sand in 2019:

1. Golf Courses & Sports Fields

Silica sand is used for bunkers and greens on golf courses, as well as for natural and synthetic sports fields. Those sand traps you find yourself stuck in way too often when you’re playing eighteen are usually full of silica sand. It’s also used to maintain greens and fairways because of its ability to support drainage and natural plant growth. For turf fields, silica sand is used as the main structural component of an uncontaminated filtration media.

2. Industrial Abrasives

Silica sand is commonly used as a mineral abrasive for industrial blasting. Though blasting with silica sand can create dangerous dust, exposure is easily avoided by following recommended PPE (personal protective equipment) guidelines and/or by coating the sand with solutions designed to control dust.

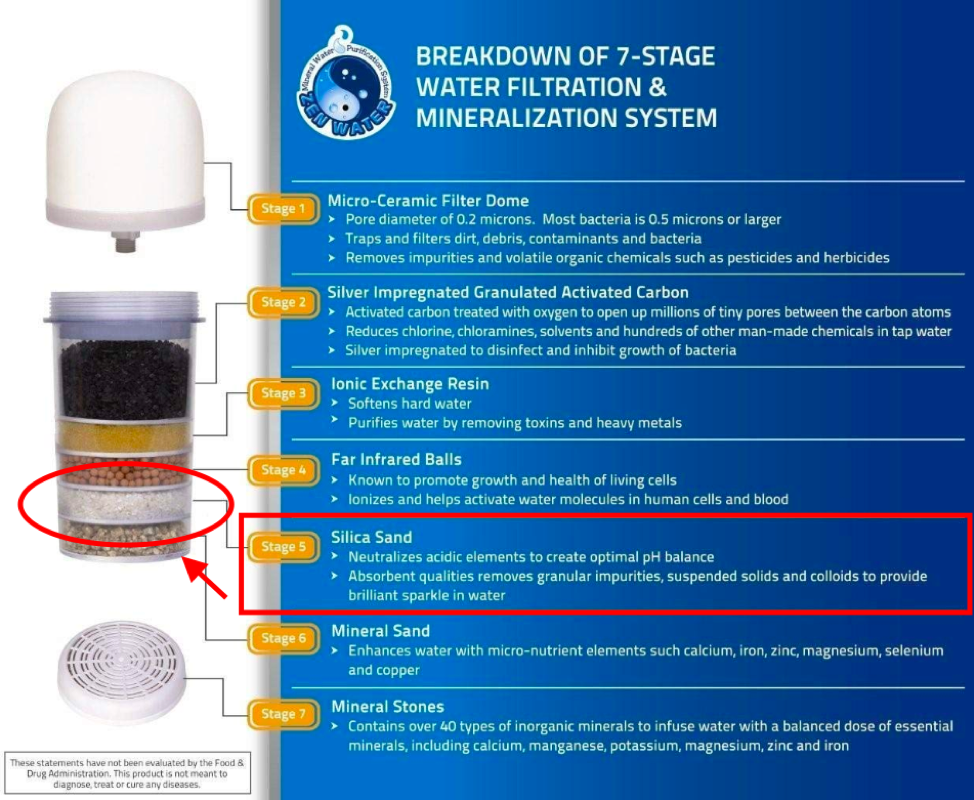

3. Water Filtration

One of the most common uses of silica sand is in water filtration, whether processing well water or filtering your tap water. Because of its uniform shape and size, silica sand is an effective filtration bed that consistently removes contaminants from water. Also, it does not degrade when exposed to acidic chemicals.

4. Glassmaking

Silica sand is a major ingredient in the production of glassmaking—in fact, silica is the primary component in standard glass products ranging from windows to beer bottles. The purity of the silica sand used plays a role in determining the color, strength and clarity of the final product.

5. Paints & Coatings

Silica sand is used in paints and coatings to improve the overall look and durability of the paint. Silica fillers improve paint’s tint reduction and dirt resistance, and because of silica sand’s oil-absorption properties it makes a durable coating that’s rich in pigment and resistant to wear and tear.

6. Ceramics & Refractories

Silica is an important component in the construction and glazing of all types of ceramics including tableware, floor tiles, wall tiles, and more. Silica serves as the structural backbone of ceramic products helping to regulate expansion and shrinkage, ensuring ceramics dry properly, and improving the overall durability of the ceramic items.

7. Construction Materials

Silica sand (often called industrial sand when used for this purpose) is the main structural component in a number of construction products. Flooring, mortars, cement, roofing shingles, asphalt, and other industrial materials all use silica to improve durability and structural integrity. As silica is resistant to weather, wear and corrosion, it is often used as a caulk or sealant.