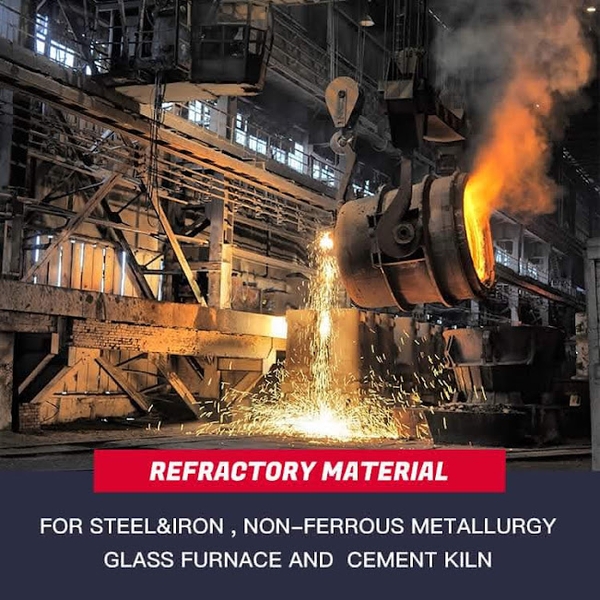

Various refractory bricks in different sizes and shapes are now available for diverse applications. The typical refractory materials include fireclay refractories, high alumina refractories, silica brick, Magnesite refractories, Chromite refractories, Zirconia refractories, Insulating materials and Monolithic refractory. Depending on temperatures and service conditions of the applications such as boilers, furnaces, kilns, ovens etc, different types of refractories are used.

Fireclay refractories

Fireclay refractories are essentially hydrated aluminum silicates with 25% - 45% Al2O3 and 50% - 80% SiO2 and minor other minerals. As fireclay brick is relatively cheap and its raw materials are widespread, it is the most common type of refractory brick and used widely in most furnaces, kilns, stoves, regenerators, etc.

Silica brick

Silica brick is a refractory material containing at least 93% SiO2. The raw material is quality rocks. Silica brick has excellent mechanical strength at temperatures approaching their actual fusion point. This behavior contrasts with that of many other refractories, for example alumino-silicate materials, which begin to fuse and creep at temperatures considerably lower than their fusion points. Various grades of silica brick have found extensive use in glass making and steel industry.

High alumina refractories

Alumina refractories containing more than 45% alumina are generally termed as high alumina materials. The alumina concentration ranges from 45 to 95%. Commonly used refractory are sillimanite (61%), mullite (70 –85%) and corundum (99%). The refractoriness of high alumina refractories increases with increase in alumina percentage. The applications of high alumina refractories includes the hearth and shaft of blast furnaces, lime and ceramic kilns, cement kilns, glass tanks and crucibles for melting a wide range of metals.

Magnesite refractories

Magnesite refractories are chemically basic materials, containing at least 85% magnesium oxide. These are made from naturally occurring magnesite (MgCO3) and Silica (SiO2). The physical properties of this class of brick are generally poor, and their great value is primarily in their resistance to basic slags, particularly to lime and iron rich slags. These constitute the most important group of refractories for the basic steelmaking processes. In addition to metallurgical furnaces, basic brick are now being successfully used in glass tank checkers and in lime and cement kilns.

Chromite refractories

Chrome-magnesite material usually contain 15-35% Cr2O3 and 42-50% MgO whereas magnesite-chromite refractories contain at least 60% MgO and 8-18% Cr2O3. Chrome- magnesite refractories are used for building the critical paths of high temperature furnaces. These materials can withstand corrosive slags and gases and have high refractoriness. The magnesite-chromite products are suitable for service at the highest temperatures and in contact with the most basic slags used in steel melting. Magnesite-chromite usually has a better spalling resistance than chrome-magnesite.

Zirconia refractories

Zirconia refractories have a very high strength at room temperature which is maintained up to temperatures as high as 15000C. Its thermal conductivity is found to be much lower than that of most other refractories. Zirconia also does not react readily with liquid metals and molten glasses. They are, therefore, useful as high temperature constructional materials for metallurgical furnaces and glass furnaces.

Monolithic refractory

Monolithic refractory, the name generally given to all unshaped refractory products, are materials installed as some form of suspension that ultimately harden to form a solid mass. Monolithic refractories are replacing the conventional type fired refractories at a much faster rate in many applications including those of industrial furnaces.

Insulating materials

Insulating materials are high porosity refractories with low thermal conductivity used in order to reduce the heat losses. Insulating materials has a lower density and offers higher thermal resistance compared to firebricks. In all cases, thermal conductivity of the insulation increases significantly as temperature increases. A wide range of insulating refractories with wide combinations of properties are now available. It is likewise cheaper in contrast to the high duty bricks.

Bình luận của bạn